HARDFACING ELECTRODES ( SMAW- MMA)

AGAINST MINERAL ABRASION ,HIGH TEMPERATURE ,CORROSION

VALVES /VALVE SEATS FORGING/STAMPING DIES For more information request our technical data sheet at office@arcwel.com

Get A Quote View Pdf| PRODUCT GOLD | PRODUCT DESCRIPTIONS

APPLICATION |

TECHNICAL DETAILS | Ø

mm |

APPLICATIONS |

| 750-SMAW (E- 630) | Stick electrode For hard facing of parts subject to mineral abrasion.

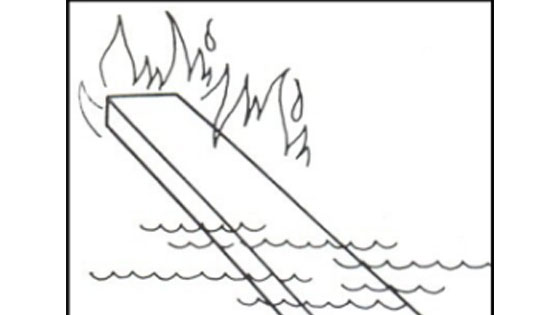

For anti rear protection in cement works, earthmoving, quarries, steelworks, foundries, and sugar industries. (Arcing) |

Hardness : ~ 58-62 HRC

Weld Metal : Chromium Carbide |

3.2

4.0 |

Mixerblades, pumps, ecavator teeth, screw presses for bricks, ( Mill roll arcing) |

| 760-SMAW (E-655) | For hard facing of parts subject to ex treme mineral abrasion and heat. Use to protect buckets, bulldozer blades, crusher rollers, impellors, screw conveyors, mixer blades, dredger teeth, fans etc. | Hardness : ~ 64HRC Weld Metal :

Chromium, Niobium, Molybdenum. |

3.2

4.0 |

Rake teeth in furnaces Slag ladles ,

Tong bits , Bucket –tips |

| 1037-SMAW (E-640) | For claddings in Sugar mills ,roughening of mill rollers increasing gripping power. | Hardness : ~ 61HRC Weld Metal :

Chromium, Carbides |

3.2

4.0 |

Mill Roller

Arcing |

| FOR HIGH TEMPERATURE COMBINED WEAR | ||||

| 1018-SMAW (HB 50 Co) | Electrode with a Co-Cr composition alloyed with Molybdenum for surfacing of parts which are subjected to a combination of metal/metal wear, corrosion and heat up to 650 °C and shortly up to 1000°C. | Hardness : ~ 45-50HRC At 20°C

After work hardening 55HRC Weld Metal : Co, Cr, Mo |

3.2 | Hot Shearblades,

Dies, building up hammers, |

| 1043-SMAW (CO1) | Extremely hard and wear resistant Cobalt, chrome tungsten alloy .

Ideal for application involving metal to met al friction such as rollers in steel mills, pump shafts rails extrusion nozzles hot cutting and forging tools………… |

Hardness : ~ 53-57HRC At 20°C

42-45HRC at 600°C Weld Metal : Cobalt Base, Tungsten, Chrome, Iron |

2.5

3.2 |

GRADE 1

COBALT BASE HIGH /ABRASION RESISTANCE |

| 1045-SMAW (Co6) | Electrode with a complex Co-Cr composi tion alloyed with W for surfacing of parts which are subjected to a combination of metal/metal wear, corrosion and heat up to 800°C and shortly up to 1000°C. | Hardness : ~ 42-45HRC At 20°C

38HRC at 60°C Weld Metal : Cobalt Base, Tungsten, Chrome, Iron |

3.2 | GRADE 6

COBALT BASE VALVES , HOT PRESS TOOLS |