COPPER –SILVER BRAZING-ALLOYS AND FLUXES

Brazing is a versatile Method allowing different metals to join without melting the base metal. The Brazing Process is used extensively in the following Industries.

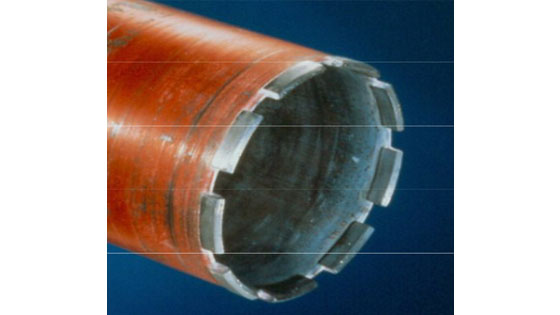

The Tool-Making Industry

- In tool manufacture

- For carbide tipped saws

- For diamond segment tipped saws

- For spectacle frames

- For medical instruments

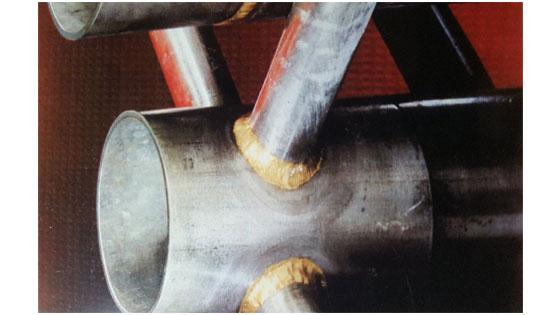

Refrigeration Engineering and Air Conditioning Technology

- Air conditioning equipment

- Refrigeration equipment

- Heat exchangers

- Heating systems

- Taps/Facets

Automotive Power Engineering and Plant Construction

- Electrical

- Motor vehicles and accessories

- Mechanical engineering

- Measuring and Control Technology

- Hydraulics

We supply a wide range of Brazing alloys to meet most Industrial Applications

| Product | Application/Features | Technical details | Form of delivery |

| 850-F

850-B |

Our most versatile brazing rod

High silver content (56 %) provides the best combination of low melting tempera ture, high strength and excellent capil lary flow, good color match on stainless steel. Use on all ferrous and non-ferrous metals (not for white metals). Ideal for application in the food industry (dairies, breweries, bottling companies, hospitals, manufacturing of lamps, etc.) |

Melting range:630-660 ºC Tensile strength:430N/ mm²

Elongation:>25 % DIN EN 1044: Analysis:Ag,Zn,Sn,Si,Cu |

B RODS.

Ø 1,5-2,0-2,5-3,0 F RODS Ø 1,5 AND 2,0 mm |

| 845 –F

845-B |

A high silver content (45 %) low tempera ture brazing rod for joining steel, stainless steel, copper, nickel and tungsten alloys. Does not contain cadmium and can therefo-re be used on food or medical equipment. Tin free composition. Highest crack resi-stance. Good ability to fill joint gaps that cannot be tightly controlled. | Melting range:640-680 ºC Tensile strength:430N/ mm²

Elongation:>25 % DIN EN 1044:AG 104 Analysis:Ag, Zn, Sn, Si, Cu |

B RODS.

Ø 1,5-2,0-2,5-3,0 F RODS Ø 1,5 AND 2,0 mm |

| 834-F

843-B |

A general purpose economical silver brazing alloy for brazing copper brass, bronze and steels.

Especially suitable for maintenance and production brazing when joint gaps are more than 0.15 mm |

Melting range:640-730 ºC Tensile strength:430N/ mm²

Elongation:>25 % DIN EN 1044: AG 106 Analysis:Ag,Zn,Sn,Si,Cu |

B RODS.

Ø 1,5-2,0-2,5-3,0 F RODS Ø 1,5 AND 2,0 mm |

Bronze Type brazing alloys for brazing steel, cast-iron, galvanized steel

| Product | Application/Features | Technical details | Form of delivery |

| 842 BB

842 FB |

Multi purpose brazing rod. For strong joints and build-ups on copper, brass, bronze, steel, galvanized and cast iron. | Melting range:875-900ºC Tensile strength:350-400N/ mm²

DIN EN 1044:CU 301 |

B (bare rods)Ø 2,0,3,0 F (flux coated) Ø

2,5mm Length 500 mm |

| 860 BB

860 FB |

Silver containing brazing alloy for joining steel, copper alloy and galva nized steel

Excellent bonding and flowing, high strength Unique flux coating allows fast and easy brazing |

Melting range:845-865ºC Tensile strength:400-450 N/ mm²

DIN EN 1044: |

B (bare rods)Ø 2,0,3,0 F (flux )Ø 2,5mm Length 500 mm |

| 865 BB

865 FB |

Special nickel bronze alloy for high strength joining and build-ups. Use for overlay-ing and build-up of gear teeth, bearings, shafts, valve seats,

wedge bars and steering knuckles, furniture and bicycle assemblies, at taching carbide cutting tips. |

Melting range:845-865ºC Tensile strength:400-450 N/ mm²

DIN EN 1044: CU 305 |

B (bare rods)Ø 2,0,3,0 F (flux coated) Ø

2,5mm Length 500 mm |

BRAZING ALLOYS FOR JOINING COPPER AND COPPER ALLOYS

| Product | Application/Features | Technical Data | Sizes

mm |

| 830 | Silver containing self fluxing brazing rod for cop per and copper alloys. High strength and ductility, excellent vibration resistance. , good electrical con ductivity. For use on air conditioning and refrigeration tubing, electric motor repairs. Radiators, heat ex changers bus bars etc.

May be used for operating temperatures up to 150 0 C |

Melting range:630-660 ºC Tensile strength:430N/mm² Elongation:>25 %

DIN EN 1044: Analysis:Ag, Cu, P |

1.5

2.0 3.0 |

| 820 | Economy type copper phosphor alloy rod for cop per.

Self fluxing on copper For use on air conditioning and refrigeration tubing, electric motor repairs. Radiators, heat exchangers bus bars etc. May be used for operating temperatures up to 150 0 C |

Melting range:630-660 ºC Tensile strength:430N/mm² Elongation:>25 %

DIN EN 1044: Analysis: Cu, P |

1.5

2.0 3.0 |

Low temperature joining (soldering) of different metals

| Product | Application/Features | Technical details |

| 22 B | A high strength solder that is free of cadmium, zinc and lead. The deposit stays bright and shiny, therefore it has a close color-match to stainless steel. Soldered joints have good corrosion resistance and can be plated. Ideal for use on stainless steel, brass, bronze, copper, nickel alloys and carbon steels. Typical applications are food and dairy equipment, instruments, jeweler manufac-turing, sanitary apparatus, electrical con nections and general maintenance repairs. 22B is a bare wire and is to be used with flux 30 FL | Melting range:220-240 ºC Tensile strength:~50 MPa Elongation:>25 %

DIN EN 1044: Analysis:,Sn,Ag Sizes: 2 and 3 mm |

FLUXES FOR BRAZING AND SOLDERING

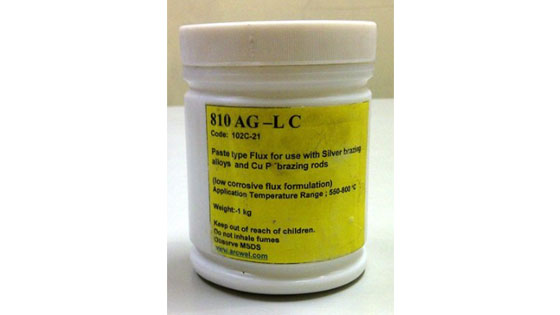

| Product | Application/Features | Technical details | Packaging |

| 810 AG | PASTE silver solder flux. Provides maxi mum wetting and cleaning action on a variety of metals. Use with 850,845,840,5045 . silver solder and other low temp brazing rods | Active range from 550 -800 °C Composition:Boric

Acid, Borates, flu borates |

1.00 kg |

| 810 HT | High temperature flux for silver brazing of nickel base alloys, mild steels, austenitic and martensitic stainless steels, tungsten carbide, Also recommended for induction brazing | Active range from 550 -800 °C Composition:

Boric Acid, Borates, flu borates |

1.00 kg

PA paste; PD powder |

| 810 CU

(21 FL) |

General purpose brazing flux in paste form. Can be used with all kinds of brazing rods for brazing steel, cast-iron, brass, bronze. Active range from 800 0 C to 11000 C. | Active range from 800 to 1100 C. Composition:

Boric Acid, Borates, flu borates |

1.00 kg |

| 40 FL

40 NC |

Universal aluminum brazing flux. Has ex cellent wetting properties on all aluminum and Aluminum alloys.

Note: 40 NC with non corrosive flux residue. |

Temp. range 440 – 650 °C

Composition:Lithium chloride Sodium chloride Potassium chloride |

1.00 kg |

| 30 FL | Universal flux for soft soldering. Rapidly dissolves oxides. Can be used on all metals except aluminum. For use with all soft-solders on stainless steel, copper, silver, galvanized steel. | Temp. range 200 – 300 °C | 1.00 kg |