Power Generation Application

Power Generation

ARCWEL supplies Maintenance and Repair alloys for most demanding and special applications in Thermal and Hydropower Generation Plants

Additional Details

SMAW Stick electrodes and FCAW-O wires for rebuilding and Hardfacing of Coal Pulverizing Grinding rollers

- ARCWEL 355 / GOLD 740 for build up

- ARCWEL 630/ GOLD 750 for hard facing

Austenitic Chrome Nickel Welding al-loys for repair of cracks on roller and build up of worn shafts.

- GOLD 330 High Strength

- GOLD 510/627 High Elongation

Nickel Base Alloys for repairs On Gas &Steam Turbines made from Alloys 600,625,800

- GOLD 510/ Ni 625 – GTAW

- ARCWEL 625– HVOF

Babbitt lined Bearings used in Ball Mill etc. tend to wear in service and require rebuilding. Worn Bearings can be recoated by

- ARCSPRAY PROCESS using ARCWEL BABBITT 90 SN wire

- This product can also be applied by the GTAW Process

Available in size 2 and 3. mm supplied on 10 kg spools

Francis, Kaplan & Pelton Turbines are used in Hydropower and commonly made from AISI 410,420, 430 Steels. The blades are subject to wear by cavitation

The following products have been used successfully for build up and repair.

- SMAW PROCESS GOLD 330 SMAW

- GTAW PROCESS GOLD 330 GTAW

Special high cavitation resistant electrodes

and wires are available on request

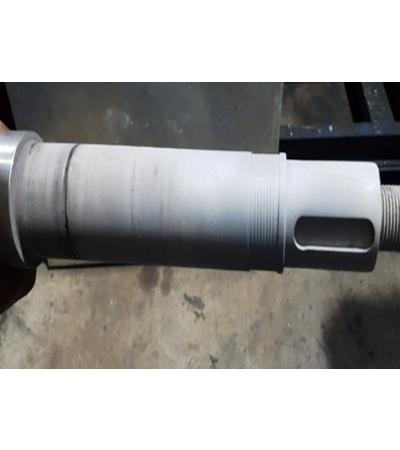

Metal Spray Powders and Spray torches for rebuilding of worn shafts

Cavitation wear on Turbine